Table of Contents

Introduction

- The concrete is made with concrete wastes which are Eco – friendly so called as Green concrete. The other name for green concrete is resource saving structures with reduced environmental impact, For e.g. Energy saving, CO2 emissions, waste water. Green concrete is a revolutionary topic in the history of concrete industry. This was first invented in Denmark in the year 1998 by Dr. WG.

- Green Concrete is a concrete building material that decreases impact on environment which does not contribute CO2 emission and decrease of corrosion and heat cracking. Green Concrete is a term give to a concrete that has extra steps taken in the mix design and placement to insure a sustainable structure and a long life cycle with a low maintenance surface.

- It is made from a combination of an inorganic polymer and between 25% and 100% industrial waste. It gains strength faster and has a lower rate of shrinkage than concrete made only from Portland Cement. Structures built using green concrete have a better chance of sustaining a fire, as it can withstand temperatures of up to 2400° F. Structure constructed from it is more resistant to temperature changes, thus saving heating and cooling costs.

Features of Green Concrete

Fig.2 Cycle Process

- Better Performance

- Enhance cohesion work ability / consistency

- Reduce shrinkage / creep.

- Durability – Better service life of concrete

- Reduce carbon footprint

- Optimizes use of available materials

- No increase in cost

- LID India Certification

Materials for Green Concrete

- Green construction materials compose of renewable things. Green materials are environmentally responsible because impacts are consider over the life of the product. Depending upon project – specific goals, green materials may involve an evaluation of one or more of the following criteria.

1. Locally available

2. Salvaged, re – furnished, or re – manufactured

3. Reusable or recyclable

Fig.3 Coarse Aggregate

Fig.4 Fine Aggregate

Cementitious materials – Fly Ash

- Fly ash is a by -product, produced during the operation of coal -fired power plants. The finely divided particles from the exhaust gases are collected in electrostatic precipitators. These particles are called as Fly ash.

- Advantages Of Using Fly Ash in Concrete:

1. Utilization of fly ash as a part replacement of cement or as a mineral admixture in concrete saves on cement and hence the emission of CO2.

2. Use of good quality of fly ash in concrete has shown remarkable improvement in durability of concrete, especially in aggressive environment.

3. Some of the technical benefits of the use of fly ash in Green Concrete are:-

a) Higher ultimate strength

b) Increase durability

c) Improve work-ability

d) Reduce bleeding

e) Increase resistance to alkali-silica reactivity.

f) Reduce shrinkage.

Suitability of Green Concretes in Structures

1. Reduce the dead weight of a structure and reduce crane age load; allow handling, lifting flexibility with lighter weight.

2. Good thermal and fire resistance, sound insulation than the traditional granite rock.

3. It improves damping resistance of building.

4. Reduction of the concrete industry’s CO2 emission by 30 %.

5. Increase concrete industry’s use of waste products by 20%.

6. No environmental pollution and sustainable development.

7. It’s require less maintenance and repairs.

8. Compressive strength behavior of concrete with water cement ratio is more than that of conventional concrete.

9. Flexural strength of green concrete is almost equal to that of conventional concrete.

Scope of Green Concrete

- They having a revolutionary topic in the history of concrete industry. As green concrete is made with concrete wastes it does take more time to come in India because of industries having problem to dispose wastes and it also reduces environmental impact with reduction in CO2 emission.

- Use of green concrete can help us to reduce a lot of wastage of several products. Various non-biodegradable products can also be used and thus avoiding the issues of their disposal.

Types of Concrete

Also read : Cement Chapter

1. Reinforced Cement Concrete

2. Plain Cement Concrete

3. Ready -mix Concrete

4. Light weight Concrete

5. Fiber reinforced Concrete

6. Green Concrete

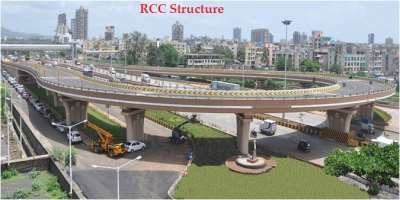

1. Reinforced Cement Concrete ( R C C )

- It is the combination of ordinary concrete with the steel to increase its compressive and tensile strength to a great extent.

- Widely use of this in the construction field.

- It reduces the size of structure.

- Sizes reduce but load bearing capacity increases.

- So, Today’s world likes this most.

- It saves money due to reduce size of structure.

- In old age, due to no use of R C C, size of place increase and also takes wide area for making place.

- For example :-

a. Buildings

b. Flyover

c. Highways roads traffic

d. Hydro -power plants

e. Tunnels

f. Irrigation canals

g. Drains ,etc.

2. Plain Cement Concrete ( P C C )

- It is the mixture of cement, fine aggregate, and coarse aggregate without steel.

- It is popularly known as P C C.

- Before starting any R C C work on ground, we first do P C C work to stop corrosion of steel.

- Save main structure from bacterial attack.

3. Ready -mix Concrete

- It never prepares on the job site.

- This prepares at central plant on a fixed batch.

- It is fully machinery made mix.

- Making construction work of this is on huge scale.

4. Light weight Concrete

- It is a type of mixture that is made with a light weight coarse aggregate and five aggregate which may be light weight.

- It oftens used in house construction.

- Reduction in dead loads making savings in foundations and reinforcement.

- Improved thermal properties.

- Improved fore resistances.

- Reduction in form work.

5. Fiber reinforced Concrete

- It is a mixture of cement, mortar or concrete with suitable fibers.

- Increases the tensile strength of the concrete.

- Reduces the air voids & water voids.

- This increases the durability of the concrete.

- It’s compressive strength is not enough.

- It does not prefer for heavy structure.

6. Green Concrete

- I have already discussed about it above.

Environmental Benefits to using Green Concrete

- Geo- polymer concrete, or green concrete, is part of a movement to create construction materials that having a reduction impact on the environment. It is made from a combination of an inorganic polymer and 25 to 100 percent industrial waste.

Here is a list of 4 benefits to using green concrete.

1. Lasts Longer

- Green concrete gains strength faster and has a lower rate of shrinkage than concrete made up of Portland Cement.

- Structures build using green concrete have a better chance of surve a fire ( it can withstand temperatures of up to 2400 degrees on the Fahrenheit scale ). It also has a greater resistance to corrosion which is important with the effect of pollution has on the environment ( acid rain greatly reduces the longevity of traditional building materials ).

- All of those factors add up to a building that will last much longer than one made with ordinary concrete. Similar concrete mixtures have been found in ancient Roman structures and this material was also used in the Ukraine in the 1950 and 1960.

- Over 40 years later those Ukrainian buildings are still standing. If buildings don’t have to be rebuilt, fewer construction materials have needed and the impact to the environment is reduced.

2. Uses Industrial Waste

- Instead of a 100 percent Portland cement mixture, green concrete uses 25 to 100 percent fly ash. Fly ash is a byproduct of coal combustion and is gathered from the chimneys of industrial plants ( such as power plants ) that use coal as a power source.

- Hundreds of thousands of acres of land are used to dispose of fly ash. A large increase in the use of green concrete in construction will provide a way to use up fly ash and hopefully free many acres of land.

3. Reduces Energy Consumption

- If you use less Portland cement and more fly ash when mixing concrete, then you will use less energy. The materials use in Portland cement require huge amounts of coal or natural gas to heat it up to the appropriate temperature to turn them into Portland cement.

- Fly ash already exists as a byproduct of another industrial process so you are not expending much more energy to use it to create green concrete. Another way that green concrete reduces energy consumption is that a building construct from it is more resistant to temperature changes.

- An architect can use this and design a green concrete building to use energy for heating and cooling more efficiently.

4. Reduces CO2 Emissions

- In order to make Portland cement – one of the main ingredients in ordinary cement – pulverized limestone, clay, and sand are heated to 1450 degrees C using natural gas or coal as a fuel. This process is responsible for 5 to 8 percent of all carbon dioxide ( CO2 ) emissions worldwide.

- The manufacturing of green concrete releases has up to 80 percent fewer CO2 emissions. As a part of a global effort to reduce emissions, switching over completely to using green concrete for construction will help considerably.

Production of Green Concrete

- Concrete with inorganic residual products. Ceramic wastes use as green aggregates. By replacing cement with fly ash, micro silica in larger amounts.To develop new green cements and binding materials ( i.e. by increasing the use of alternative raw materials and alternative fuels, and by developing / improving cement with low energy consumption ).

- To use residual products from the concrete industry, i.e. stone dust ( from crushing of aggregate ) and concrete slurry ( from washing of mixers and other equipment ). To use new types of cement with reduced environmental impact. ( mineralized cement, limestone addition, waste – derived fuels ).

Green Lightweight Aggregates

- Synthetic lightweight aggregate produces from environmental waste is a viable new source of structural aggregate material. The uses of structural grade lightweight concrete reduce considerably the self -load of a structure and permit larger precast units to be handled.

- Water absorption of the green aggregate is large but the crushing strength of the resulting concrete can be high. The 28 days cube compressive strength of the resulting lightweight aggregate concrete with density of 1590 kg/m³ and respective strength of 34 MPa. Most of normal weight aggregate of normal weight concrete is natural stone such as limestone and granite.

Advantages

- It will give increase same particle attraction so user friendly – easier to place, compact & finish concrete. It can be seen in concrete slump.

- Optimize mix designs mean easier handling, better consistency and easier finishing.

- Reduction in shrinkage & creep.

- They use local and recycled materials in concrete.

- The heat of hydration of green concrete is significantly lower than traditional concrete.

- This result in a lower temperature rise in large concrete pours which is a distinct advantage for green concrete.

- It decreases wastage of materials and opens way of use of waste materials in this generation.

Improved Engineering Properties

- Mix can result in a reduced paste volume within the concrete structure resulting in a higher level of protection against concrete deterioration.

- Higher strength per kilogram of cement.

- Increase durability & lower permeability.

- More aggregates typically mean higher Modulus of elasticity.

Limitation

- By using stainless steel, cost of reinforcement increases.

- Structures constructed with green concrete have less life than structures with conventional concrete.

- Split tension of green concrete is less than that of conventional concrete.

- Corrosion in the steel bars can also occur if the aggregates used are not free from corrosion leading agents.

Necessity to Produce Green Concrete

- To giving a better as well as healthy environment for coming generation.

- Making use of huge amount of bad concrete which comes from breaking of old buildings, old bridges, etc.

- Reducing as well as decreasing, the increasing amount of CO2 gas in the environment.

- To increase the use of conventional residual products, i.e. fly ash.

- Using residual products from the concrete industry, i.e. stone dust ( from crushing of stones ).

- To use residual products from other industries not traditionally used in concrete, i.e. fly ash from bio fuels and sewage sludge incineration ash.

- To use new types of cement with reduced environmental impact.

Conclusion

- Green concrete have reduced environmental impact with reduction of the concrete industries CO2 omissions by 30%. They have good thermal and fire resistant. In this concrete recycling, use of waste material such as ceramic wastes and aggregates increase concrete industry waste products by 20%.

- Hence, they consume less energy and becomes economical. So, the use of concrete product like green concrete in future will not only reduce the emission of CO2 in environment and environmental impact but it is also economical to produce.

For better understanding watch this video clip

https://www.youtube.com/watch?v=bktXNSpCEEo