Table of Contents

Cochran Boiler

A Cochran boiler is a type of vertical, fire-tube boiler with a multi-tubular design.

It is a modification of a simple vertical boiler commonly used in smaller industrial applications due to its simplicity and efficiency.

It operates by burning fuel in a furnace, transferring the heat from the resulting hot gases to water surrounding the fire tubes, and then collecting the generated steam at the top of the boiler.

- The boiler is characterized by a cylindrical shell and a hemispherical firebox, and multiple horizontal fire tubes through which hot gases pass, heating the surrounding water to produce steam.

- It is made in various sizes of evaporative capacities ranging starting from 150 to 3000 kg/hr and working pressures of up to 15 bar.

- The Cochran boiler was founded by Cochran & Co. of Annan.

- The productivity of this boiler is obviously superior to the straightforward vertical heater.

Definition of Cochran Boiler

A Cochran boiler is a type of vertical, fire-tube boiler with a multi-tubular design used for small-capacity steam generation.

- They have cylindrical shell with a dome shape top where the space is provided for steam.

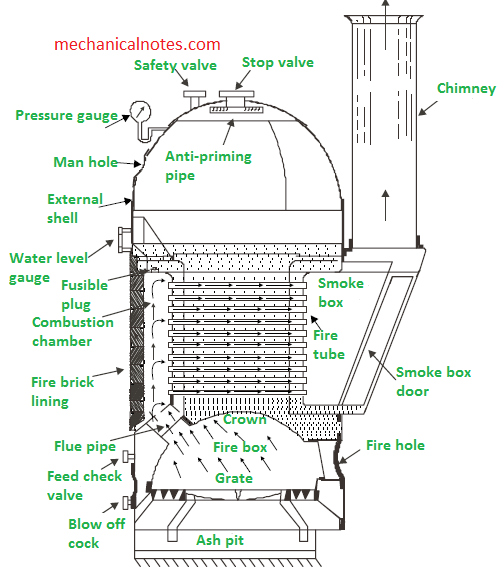

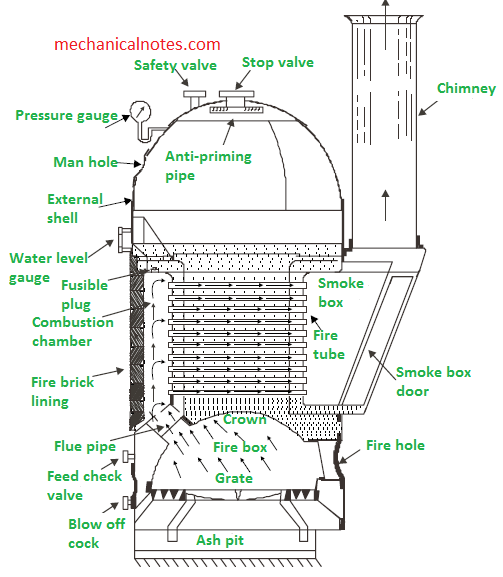

Fig. Cochran Boiler line Diagram.

- There are 11 main parts of cochran boiler:-

1. Boiler Shell

- A shell is the main body of the boiler.

- They having vertical axis cylindrical drum with hemispherical dome type shell at the top.

- This hemisphere gives higher volume to increase steam capacity.

2. Combustion chamber

- The combustion chamber is below the boiler shell for burning the fuel.

3. Grate

- The grate is a platform where fuel is burnt.

- It is basically made of cast iron.

- And there is space between them so the air can pass through it.

- The surface area of the grate where fire takes place called a grate surface.

4. Fire tubes

- The fire tubes are the horizontal tubes that are present between the combustion chambers.

- The flue gases from the combustion chamber flow to the smokebox via a number of fire tubes.

- These fire pipes are used to exchange heat from hot flue gases to water.

5. Fire hole

- It is at the bottom of the combustion chamber for firing fuel inside the furnace.

6. Furnace (Fire box)

- The furnace is above the grate and below the boiler shell.

- And in the furnace, the fuel is burned.

- It is also named as fire box.

7. Ash pit

- Ash pits are present below the grate, where they accumulate ashes generated during combustion.

8. Chimney

- It is provided at the top of the boiler where it is connected to the smokebox.

- Here exhaust gases are coming out from fire tubes and pass through smokebox and exhaust through a chimney.

9. Fire brick lining

- It is a special type of brick lining that is used in cochran boiler to reduce the convection of heat from the outer surface of the boiler.

- It is basically made of fire clay.

10. Man hole

- It is a hole on the boiler shell for the purpose of either cleaning, inspection and maintenance.

11. Flue pipe

- It is a short pipe where it is connected with the fire box and combustion chamber.

- Hence, these pipes are called flue pipes.

- The hot flue gases from the grate flow into the combustion chamber via flue pipe.

Also read : Boiler Definition, Parts, Components , etc.

Construction of Cochran Boiler

- The Cochran boiler is made of a cylindrical shell, a hemispherical fire box, fire tubes, and a chimney.

- The top of the shell has a hemispherical-shaped crown.

- Its hemisherical crown gives good strength to the pressure of steam inside the boiler.

- The hemispherical shape of the furnace can withstand high heat and is also useful to increase radiant heat transfer from the furnace to the hemispherical furnace wall.

- The grate is placed at the bottom of the furnace, where the ash pit is located below the grate.

- Its furnace and the combustion chamber are connected by a short flue pipe.

- The wall of the combustion chamber is lined with fire bricks.

- At last, the ash pit is located below the grate.

Working of Cochran Boiler

- Fuel is placed at the grate through fire hole.

- Air comes into the combustion chamber through atmosphere.

- Fuel is burn through fire hole.

- Then, the hot flue gases emerge out and start flowing into hemispherical dome shaped combustion chamber.

- This hot flue gases further moves into the fire pipes.

- The hot flue gases inside the fire tubes exchange the heat from the hot gases to the water.

- Due to the exchange of heat, the steam produced. And it rises upward to collect into the upper side of the shell.

- When the required pressure generated, the flue gases goes to the chimney through fire box where it leaves to the atmosphere.

- Hence, this process repeats and run continuously.

Features of Cochran Boiler

- In Cochran boiler, any types of fuel may be used.

- It gives 70% to 75% of thermal efficiency with coal and oil firing.

- It is well suitable for small capacity requirement.

- The ratio of grate area to the heating surface area varies from 10:1 to 20:1.

Specification of the Cochran boiler

| Height | 5.75 m |

| Efficiency | 70 – 75 % |

| Shell diameter | 2.75 m |

| Steam capacity | 3500 kg/hr (max. 4000 kg/hr) |

| Working pressure | 6.5 bar( max. 15 bar) |

|---|---|

| Heating surface area | 120 m |

Advantages of Cochran boiler

- It occupies less floor space.

- Initial cost of boiler is less.

- It is easy to operate.

- Low initialization cost.

- They having higher volume to area ratio.

- Easy to clean and inspect.

- It’s easy to transport from one place to another.

Limitations of Cochran boiler

- Maintenance and inspection are difficult due to narrow space inside for entering.

- They having limited pressure range.

- Steam generation rate is low.

- Due to it’s vertical design, high room head is required for its installation.

Different types of Mounting used in Cochran boiler

- The Mountings are those mechanical appliances which are considered essential for operating a boiler smoothly and safety. Which are normally mounted on the outside of a heater.

The following are the important mountings of a boiler:

1. Safety valves

2. Fusible plug

3. Pressure gauge

4. Water level indicator

5. Blow off cock

6. Feed check valve

7. Steam stop valve

1. Safety valves

- It is utilized to forestall blast because of extreme inward weight.

- Safety valves are attached on the chest of the boiler.

- General, there are two safety valves are present on a boiler.

2. Fusible plug

- The function of a fusible plug is to ensure safety to the boiler from begin damaged by overheating due to water level falling very low in the boiler.

3. Pressure gauge

- It application is to measure the pressure of the steam which is present inside the boiler.

- It’s also present in front of the boiler.

4. Water level indicator

- It shows the immediate degree of water that’s accessible within the steam evaporator.

5. Blow off cock

- It is situated at the bottom of the boiler drum.

Purpose of Blow off cock:

i. To empty the boiler.

ii. To discharge the dimensions, mud and sediments.

6. Feed check valve

- It regulates the supply of water that is pumped into the boiler by feed pump.

7. Steam stop valve

- It is normally fitted on the most noteworthy piece of the heater with the assistance of a spine.

The main functions are as follows:

i. To regulate the flow of steam from the boiler to the moststeam line.

ii. To fully shut off the steam provide.

Different types of Accessories used in Cochran boiler

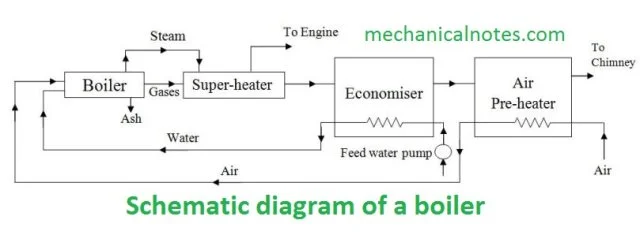

1. Economizer

2. Feed pump

3. Super heater

4. Air preheater

1. Economizer

- It improves the economy of the boilers.

- It is used to heat the feed water by the application of heat from the hot fuel gases before it leaves the chimney.

Advantages of Economizer:

- The long life of the boiler.

- To increase in the evaporative capacity of the boiler.

2. Feed pump

- It use to deliver water to the boiler.

There are mainly two types of feed pump:

i. Reciprocating feed pump

- This is positive displacement type pumps. The most popular types of reciprocating feed pump used in a boiler is a duplex feed pump.

- It consists of a steam engine and a water pump side by side.

ii. Rotary feed pump

- It is a high speed centrifugal pump that is used to deliver a large quantity of water into the boiler.

- It consists of impeller and casing.

3. Super heater

- It is a heat exchanger in which products of the heat of combustion is utilized to dry the wet steam and to make super heated by increasing it’s temperature.

- During this process, pressure remains constant and it’s volume and temperature increase. It consists of a set of small diameter U – tube in which steam flows and takes up the heat from hot flue gases.

Advantages:

- To increase overall efficiency.

- There is a saving in fuel consumption.

4. Air preheater

- It is a device which designed to heat air before another process with the primary objective of increasing the thermal efficiency of the process.

For Better Understanding Watch This Video Clip

https://www.youtube.com/watch?v=hVcqqaEulVA

→ https://mechanicalnotes.com/centrifugal-pump-definition-types-parts-working-and-diagram/

You explain very well sir 👍👍

Nice explnation sir.

Thanks…